Our couplings are based on Shape Memory Metal technology using

Tinel, a nickel and titanium-based alloy. When Tinel is exposed below a specific

temperature, it can be mechanically deformed. However, when the temperature

is raised, Tinel returns to its predetermined shape. This shape change occurs

at a unique transformation temperature determined by the alloy composition.

We've discovered that the cycle can be successfully repeated with consistent

results. The Tinel alloy's composition allows for control of such properties

as transformation temperature, yield strength, and consistent recovery stress.

There are Two Sides to Every Crystalline Structure .

Tinel exists in one of two stable crystalline phases: a high-temperature

phase called austenite, and a low-temperature phase called martensite. In

the austenitic phase, the crystalline structure is body-centered cubic. When

cooled below its transformation temperature, the austenitic structure undergoes

a diffusionless shear transformation to a highly-twinned martensite crystal

structure.

In this martensitic phase, the twinned structure can be mechanically

deformed to a parallel registry. This deformation of approximately eight percent

remains as long as Tinel is below its transformation temperature. However,

when the deformed martensitic structure warms through its transformation temperature,

it returns immediately to the aystensitic form. Left unrestricted, the Tinel

will return to its original shape.

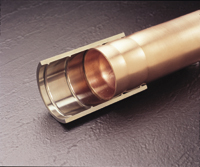

Our SMARTFIT® Couplings are Chilled to Perfection.

Made from Tinel, the SMARTFIT® coupling - or sleeve - is machined at room

temperature, in its high strength (austenitic) state, to an inside diameter

slightly smaller than the pipes or tubes it is to join. The component is then

cooled in liquid nitrogen and the metallurgical characteristics of the alloy

change to the lower strength (martensitic) state. With the coupling in this

lower strength, cooled state, a tapered mandrel is driven through its center,

expanding the inside diameter of the coupling. The coupling remains in cold

storage in its expanded condition until ready for use. It is then removed

from this container and slipped over the tube or pipe ends to be joined. As

the coupling warms to room temperature, it reverts back to its high-strength

state and attempts to recover to its original shape while exerting tremendous

radial force. This permanent, live-crimp action establishes a leak-free, metal-to-metal

seal between the coupling and the tubes or pipe throughout the life of the

joint.

Click one of the following links to see how this technology works:

Flash version

Standalone Version